In today's fast-paced business world, companies need effective tools to stay competitive. Deming's 14 Points offer a proven framework for improving quality and productivity. These principles, developed by W. Edwards Deming, help businesses create a culture of continuous improvement. By adopting these points, organizations can enhance their processes, reduce costs, and increase customer satisfaction.

This article will delve into Deming's 14 Points of quality management and explore their relevance in today's business environment. We will explain each of the 14 components in detail and provide practical examples to illustrate their application. Additionally, we will discuss the benefits and potential drawbacks of implementing these principles in your organization. We will also see suitable environments and common queries.

Let’s start with the definition: What are Edward Deming’s 14 Points?

Deming's 14 Points is a set of management practices designed to help companies improve quality and productivity.

Developed by W. Edwards Deming, these principles emphasize the importance of continuous improvement and a holistic approach to management. Deming believed that by adopting these points, businesses could reduce waste, improve efficiency, and increase customer satisfaction.

Deming’s 14-point summary focuses on fostering a culture of quality. It encourages all employees to take part in the improvement process. This means that companies should have a long-term vision and stay committed to their goals. Short-term thinking can lead to poor decision-making and hinder progress.

Another key point is the importance of adopting a new philosophy. Deming argued that traditional management practices were outdated and ineffective. Companies should embrace modern quality management principles to stay competitive. This involves shifting from a focus on short-term profits to long-term growth and sustainability.

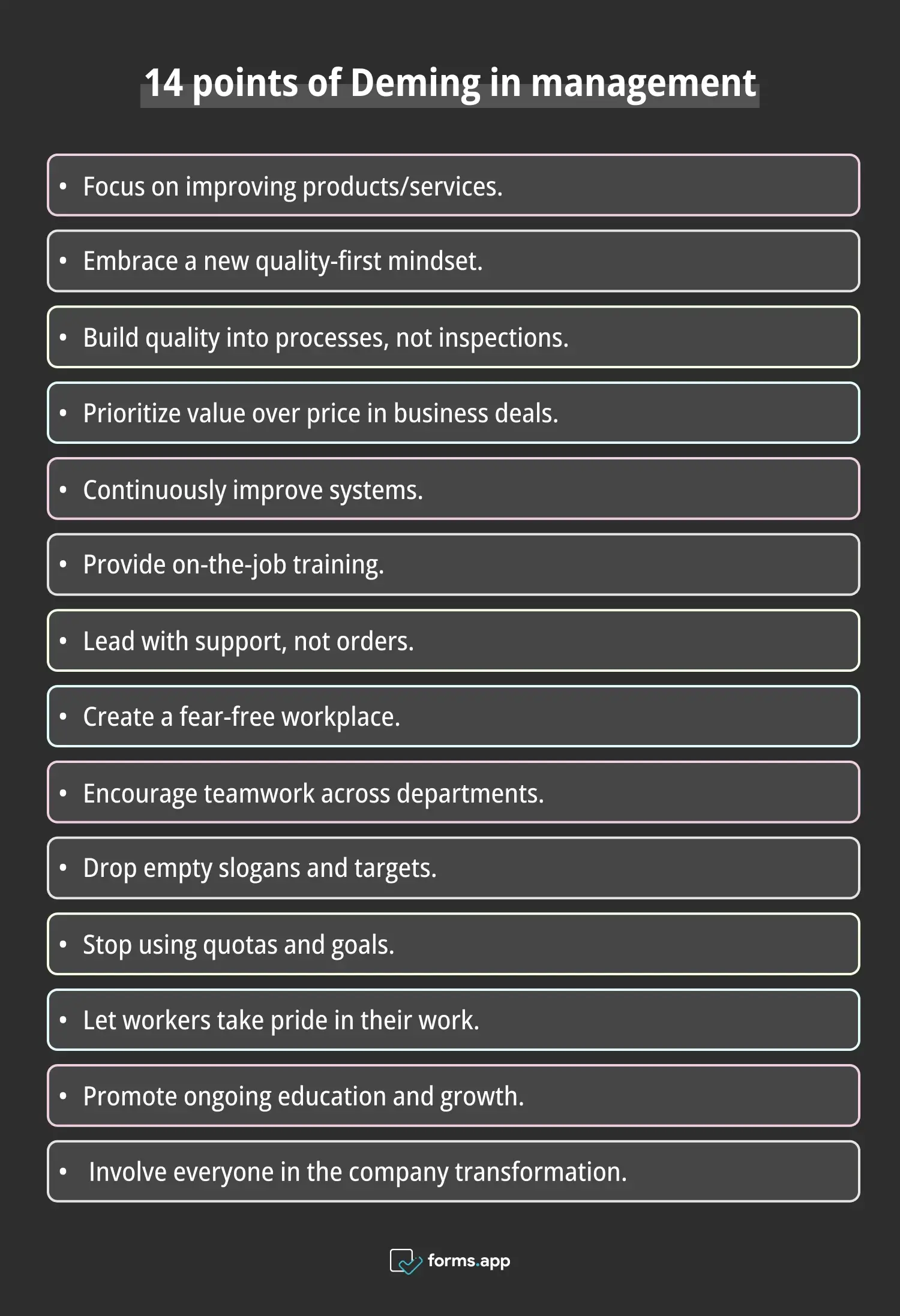

14 Points of Deming in management

Now, let’s delve into the 14 points of Deming in management. We’ll take each of the points in detail. By understanding and applying these principles, you can enhance your organizational quality, efficiency, and overall performance. Each point offers valuable insights and actionable steps to drive continuous improvement and achieve long-term success.

Deming’s 14 points

1- Create constancy of purpose for improving products and services

Establish a long-term vision for your organization that emphasizes quality and continuous improvement. This requires a commitment to invest in research and development, employee training, and process improvements. Avoid short-term decisions that may provide quick profits but compromise long-term goals.

Consistency of purpose helps align the entire organization towards common objectives, creating a strong foundation for sustainable growth. You can maintain a steady focus on quality and customer satisfaction. Your business can build a reputation for reliability and excellence. This, in turn, leads to increased customer loyalty and market share.

2- Adopt the new philosophy

Embrace a culture of quality and continuous improvement. Recognize that traditional management practices may no longer be effective in today’s competitive environment. Shift from a focus on short-term gains to long-term sustainability. This new philosophy involves adopting modern quality management principles.

These principles prioritize customer satisfaction and process efficiency. Leaders must drive this cultural change, encouraging innovation and learning at all levels of the organization. By adopting this new way of thinking, companies can create a more agile and resilient business model. It will be capable of adapting to changing market conditions and emerging opportunities.

3- Cease dependence on inspection to achieve quality

Instead of relying solely on inspections to catch defects, focus on building quality into the product from the start. Inspections can be costly and inefficient, often identifying problems too late. Implementing robust quality control processes during production helps prevent defects from occurring in the first place.

Use statistical process control and other quality management tools to monitor and improve processes. By reducing the need for inspections and rework, businesses can lower costs and increase efficiency. They can also deliver higher-quality products to customers consistently.

4- End the practice of awarding business on price alone

Selecting suppliers based solely on price can lead to subpar products and services. Instead, consider other critical factors such as quality, reliability, and the supplier’s commitment to continuous improvement. Build long-term relationships with suppliers who share your commitment to quality.

Collaborate with them to develop better materials and processes. This can lead to cost savings and improved products over time. By prioritizing quality in your supplier relationships, you can create a more stable supply chain. Your supply chain will support your organizational long-term goals and enhances overall performance.

5- Improve constantly and forever the system of production and service

Continuous improvement should be an ongoing goal for every organization. Use feedback from customers, employees, and other stakeholders to identify areas for improvement. Implement small, incremental changes rather than drastic overhauls, as these are easier to manage and sustain.

Employ tools like Plan-Do-Check-Act (PDCA) cycles to test and refine improvements. Foster a culture where you encourage employees to suggest and participate in improvement initiatives. By seeking ways to enhance processes and systems, businesses can stay competitive and adapt to evolving market demands.

6- Institute training on the job

Providing ongoing training and development opportunities for employees is crucial for maintaining high-quality standards. Ensure that employees have the necessary skills and knowledge to perform their jobs effectively. Training should be a continuous process, not a one-time event. Include training on new technologies, processes, and quality management principles.

Encourage a culture of learning where you motivate employees to improve their skills and take on new challenges. Well-trained employees are more productive, engaged, and capable of contributing to the organization’s goals of quality. Remember, the companies are only as capable as their employees.

7- Institute leadership

Effective leadership is essential for guiding employees and driving organizational success. Leaders should focus on helping employees improve their work rather than simply giving orders. This involves providing support, resources, and encouragement. Create an environment where employees feel the value and motivation to do their best.

Leadership also means setting a clear vision and communicating it effectively throughout the organization. By fostering a culture of trust and respect, leaders can inspire their teams to achieve higher performance. They can also contribute to the organization’s continuous improvement efforts.

8- Drive out fear

Fear can stifle creativity, innovation, and productivity. Create a safe environment where employees feel comfortable expressing their ideas and concerns. Encourage open communication and collaboration. Address issues promptly and fairly to build trust within the organization.

Employees should not be afraid of making mistakes or speaking up. They will be more likely to contribute to improvement initiatives and suggest innovative solutions. By driving out fear, organizations can create a more dynamic and engaged workforce. This workforce is committed to achieving common goals and continuous improvement.

9- Break down barriers between departments

Siloed departments can lead to inefficiencies and hinder progress. Encourage teamwork and cooperation across the organization. Facilitate cross-functional teams to work on projects and solve problems collaboratively. By breaking down barriers, you can ensure that everyone is working towards the same objectives.

You will also ensure that everyone will share valuable information and resources. This collaborative approach fosters a sense of unity and shared purpose. This can lead to better decision-making and more innovative solutions. When departments work together seamlessly, the organization becomes more agile and effective.

10 - Eliminate slogans, exhortations, and targets for the workforce

Slogans and targets can create confusion and frustration among employees. They often emphasize outcomes without addressing the underlying processes that need improvement. Instead of setting arbitrary targets, focus on creating systems and processes that enable employees to perform their best.

Provide guidance, training, and resources to help employees achieve their goals. By improving the work environment and processes, you can achieve better results. You can do so without relying on motivational slogans or unrealistic targets. This approach leads to a more engaged and productive workforce.

11- Eliminate numerical quotas for the workforce and numerical goals for management

Quotas and numerical goals can lead to short-term thinking and suboptimal practices. Employees may cut corners or engage in unethical behavior to meet targets. Instead, focus on continuous improvement and process optimization. Encourage employees to find better ways of doing their work rather than simply meeting quotas.

Use performance metrics to identify areas for improvement, but do not make them the sole focus. By prioritizing quality and continuous improvement, you can achieve sustainable results and create a more positive work environment.

12- Remove barriers that rob people of pride in their work

Ensure that you value and appreciate employees for their contributions. Recognize and reward their efforts to improve quality and processes. Remove obstacles that prevent employees from taking pride in their work. These obstacles may include inadequate resources, poor management practices, or lack of recognition.

Create an environment where employees can take ownership of their tasks and feel accomplished. When employees are proud of their work, they are more motivated and engaged. This leads to higher productivity and better outcomes for the organization.

13- Institute a vigorous program of education and self-improvement

Encourage continuous learning and personal development for all employees. Provide ample opportunities for training, education, and skill enhancement. Support employees in pursuing professional certifications, attending workshops, participating in relevant industry events, and engaging in online courses. This investment in employee growth fosters innovation and drives organizational success.

A culture of continuous learning helps employees stay up-to-date with the latest developments in their field. It also contributes to overall organizational improvement. By investing in your employees’ growth, you can build a more knowledgeable and capable workforce.

14- Put everybody in the company to work accomplishing the transformation

Engage all employees in the process of continuous improvement. Everyone, from top management to frontline workers, should take part in achieving the organization’s goals. Create a culture where employees feel responsible for contributing to quality and improvement efforts. Encourage collaboration and communication across all levels of the organization.

By involving everyone in the transformation process, you can harness the collective knowledge and skills of your workforce. This will drive meaningful and sustainable improvements. This inclusive approach ensures that the entire organization aligns with and commits to achieving long-term success.

Why to use Deming’s 14 Points

Now, let's explore why Deming’s 14 Points in management should be used. By implementing these principles, you’ll be able to foster a culture of continuous improvement. You’ll also enhance product and service quality and achieve sustainable growth. These points offer a strategic framework to optimize organizational processes and drive long-term success.

⬆️ Improved quality: By following Deming's 14 Points, organizations can enhance the quality of their products and services. This leads to higher customer satisfaction and loyalty. Improved quality also reduces waste and rework, saving time and money.

📈 Increased efficiency: Implementing these principles helps streamline processes and eliminate inefficiencies. This results in faster production times and lower operational costs. Efficient processes enable companies to respond quickly to market changes and customer demands.

👨🏻💻👩🏻💻 Employee engagement: Involving employees in the improvement process boosts morale and engagement. When employees see their contributions making a difference, their motivations and efficiency will increase.

🤝 Customer satisfaction: Consistently delivering high-quality products and services enhances customer satisfaction. Satisfied customers are more likely to return and recommend your business to others, driving growth and profits.

💸 Reduced costs: Continuous improvement leads to cost savings by eliminating waste and improving efficiency. Lower costs allow companies to invest in innovation and growth, providing a competitive edge in the market.

✨ Innovation: A culture of continuous improvement encourages creativity and innovation. Employees are more likely to suggest new ideas and solutions when they actively participate in the improvement process.

🏆 Competitive advantage: Companies that adopt Deming's 14 Points are better positioned to compete in the market. High-quality products, efficient processes, and engaged employees give businesses a significant advantage over their competitors.

🚀 Sustainable growth: Focusing on long-term improvement rather than short-term gains ensures sustainable growth. Companies that prioritize quality and continuous improvement are more resilient and adaptable to changing market conditions.

Examples of Deming’s 14 Points

Now, let's examine practical examples illustrating Deming’s 14 Points in action. These scenarios demonstrate how organizations have applied these principles to improve quality, efficiency, and customer satisfaction. You’ll gain insights into the real-world application and benefits of Deming’s principles in diverse business contexts.

1- Manufacturing company

A manufacturing company implemented Deming's 14 Points to improve product quality. By focusing on process improvements and employee training, they reduced defects by 50%. This led to higher customer satisfaction and increased sales. The company also saw a significant waste reduction, saving thousands of dollars annually.

2- Healthcare provider

A healthcare provider used Deming's principles to enhance patient care. They focused on improving communication and collaboration among staff. As a result, patient satisfaction scores increased, and the number of medical errors decreased. The provider also implemented continuous training programs, leading to better patient outcomes.

3- Software development firm

A software development firm adopted Deming's 14 Points to streamline its development process. By emphasizing teamwork and continuous improvement, they reduced the time to market for new products. This increased their competitiveness and customer satisfaction. The firm also saw a boost in employee morale and productivity.

Advantages and Disadvantages

Now, let's explore the advantages and common challenges of implementing Deming’s 14 Points. Understanding these benefits and potential obstacles will provide insights into how organizations can effectively leverage these principles to achieve sustainable improvement and competitive advantage.

Advantages:

➕ Higher quality: Deming’s 14 Points emphasize continuous improvement and customer focus, enhancing product and service quality. This leads to increased customer satisfaction, loyalty, and a competitive edge in the market.

➕ Cost savings: By reducing waste and inefficiencies, organizations lower operational costs and improve profits. This allows for strategic reinvestment in innovation, expansion, or further quality improvements.

➕ Employee motivation: Engaging employees in improvement initiatives fosters a positive workplace culture. It boosts morale, productivity, and innovation, driving organizational success and employee retention.

➕ Customer trust: Consistently meeting quality standards builds trust and enhances brand reputation. This results in customer loyalty and positive word-of-mouth referrals.

➕ Innovation: A focus on continuous improvement stimulates creativity and innovation throughout the organization. It encourages new ideas and solutions to emerge, keeping the organization competitive and adaptable to market changes.

➕ Operational efficiency: Streamlined processes and optimized workflows improve efficiency and resource allocation. This allows organizations to respond faster to customer demands and market changes.

➕ Competitive edge: Implementing Deming’s principles sets organizations apart from competitors by delivering superior quality and value. It establishes a reputation for reliability and excellence in products or services.

➕ Sustainable growth: Building a culture of continuous improvement ensures long-term sustainability and growth. It strengthens organizational resilience and adaptability in dynamic business environments.

Disadvantages:

➖ Implementation costs: Initial investments in training, technology, and process redesign can be substantial, impacting short-term financial resources.

➖ Resistance to change: Employees and stakeholders may resist adopting new practices, hindering effective implementation and organizational buy-in.

➖ Time-consuming: Continuous improvement requires ongoing commitment and resources. This potentially diverts attention from day-to-day operations and short-term goals.

➖ Complexity: Managing all 14 points and integrating them into existing processes can be complex, requiring coordinated efforts across departments and levels of the organization.

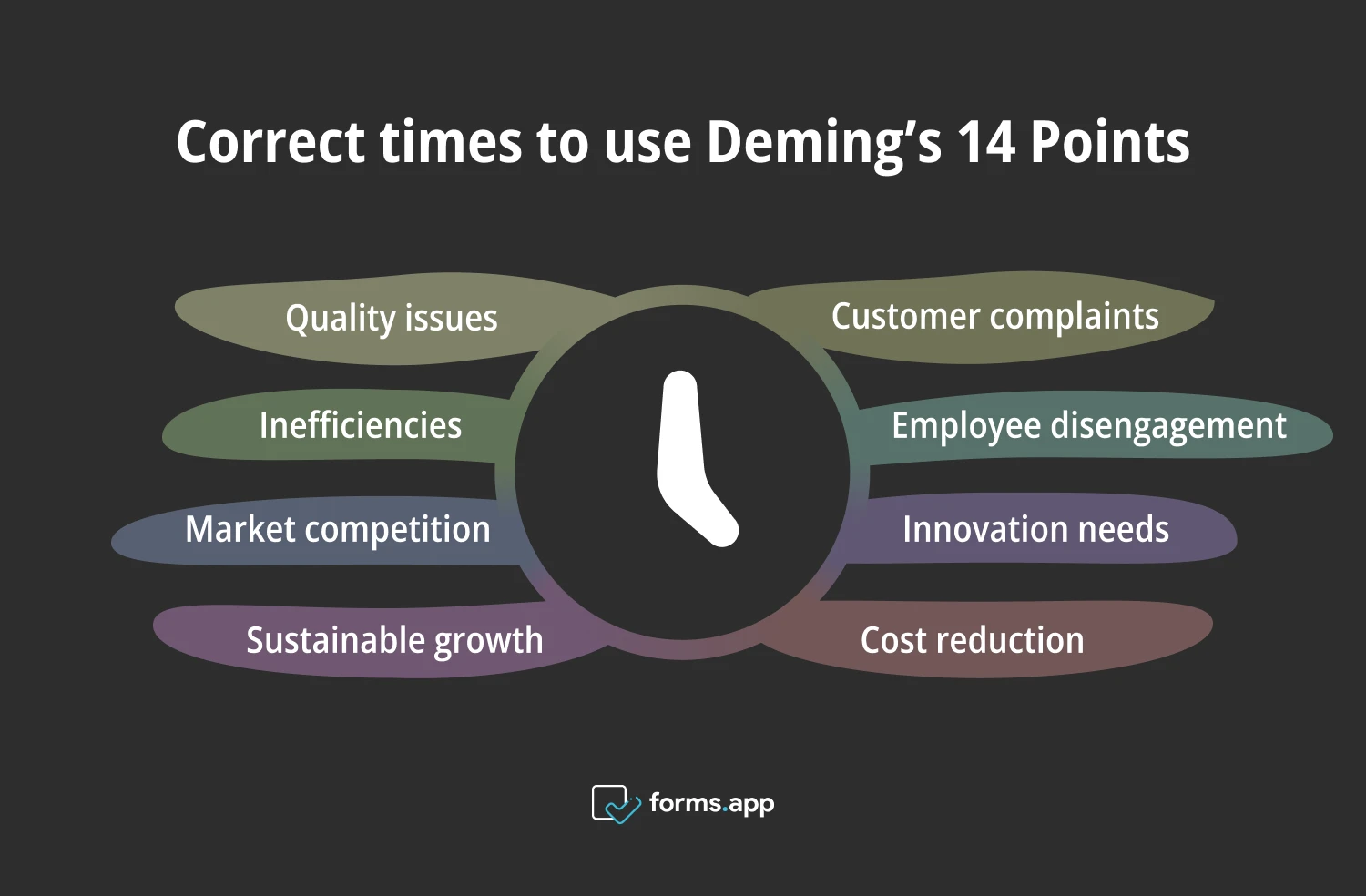

When to Use Deming’s 14 Points

Let's delve into when to use Deming’s 14 Points. Identifying the right circumstances for applying these principles is crucial for maximizing their effectiveness in enhancing quality, efficiency, and organizational performance. By understanding these strategic applications, organizations can proactively address challenges.

Right times to use Deming’s 14 points

⏰ Quality issues: When facing persistent quality issues, Deming’s 14 Points pinpoint root causes and drive systematic improvements. It ensures sustained enhancements in product and service quality. This approach bolsters customer satisfaction and loyalty by addressing underlying issues and improving reliability.

⏰ Customer complaints: Implement these principles to address customer feedback effectively. It will refine processes to meet expectations consistently. It will also enhance satisfaction through continuous improvement and proactive quality management practices. By responding to customer needs promptly, businesses can build trust and loyalty, ensuring long-term success in competitive markets.

⏰ Inefficiencies: Use to streamline operations, eliminate waste, and optimize resource use for enhanced productivity and cost efficiency. This ensures operations align with organizational goals and customer expectations while maintaining high standards of quality and service delivery.

⏰ Employee disengagement: Apply to boost morale and engagement by involving employees in decision-making and improvement initiatives. This will foster a supportive workplace culture that encourages innovation, continuous learning, and personal growth. Engaged employees are more motivated and productive, contributing to organizational success and resilience.

⏰ Market competition: Utilize for competitive advantage by delivering superior quality and service. It will set your business apart through continuous improvement efforts that meet evolving market demands and enhance customer experience. It will also maintain a leading position in the industry. This proactive approach ensures responsiveness to market changes and customer preferences.

⏰ Innovation needs: When innovation is critical, these principles foster creativity and adaptation. It encourages new ideas and approaches that drive ongoing improvement, market relevance, and organizational growth. By nurturing a culture of innovation, businesses can anticipate market trends and capitalize on emerging opportunities for strategic advantage.

⏰ Sustainable growth: Implement stable, long-term growth by embedding quality and efficiency into organizational practices. This ensures resilience, agility, and strategic alignment with market dynamics and customer needs. This fosters sustainable business development and market leadership.

⏰ Cost reduction: Apply to identify and eliminate inefficiencies, reducing costs while maintaining or enhancing product and service quality. This leads to improved profits, financial health, and competitive positioning in the market, ensuring sustainable cost management and operational excellence for long-term success.

Frequently asked questions about Deming’s 14 Points

Let's address some common questions about Deming's principles. These FAQs provide insights into key concepts such as the Deming cycle, the 94/6 rule, and fundamental principles. Understanding these concepts is essential for implementing effective quality management and continuous improvement strategies within organizations.

The Deming cycle, also known as PDCA (Plan-Do-Check-Act), comprises four connected stages essential for continuous improvement. These are as follows: Plan, where objectives and processes are established; Do, implementing the plan and collecting data; Check, evaluating outcomes against expectations and identifying gaps; and Act, adjusting processes to improve efficiency and quality based on findings.

The Deming 94/6 rule highlights that a vast majority (94%) of quality issues stem from deficiencies in systems and processes rather than individual mistakes (6%). This principle emphasizes the critical importance of refining and enhancing organizational systems to achieve consistent quality and efficiency across operations.

Deming's basic principles include focusing on customer needs and satisfaction. It also entails adopting a systems approach to management and involving employees in continuous improvement. Moreover, we can count on using data-driven decision-making and pursuing a commitment to quality throughout the organization. These principles aim to achieve long-term success and competitive advantage.

Conclusion

To sum up, Deming's 14 Points provide a comprehensive framework for improving quality and efficiency in any organization. By focusing on continuous improvement and involving all employees in the process, businesses can achieve long-term success. Implementing these principles leads to higher-quality products, cost savings, and customer satisfaction.

This article covered Deming's 14 Points, their detailed explanation, and their application in real-world scenarios. We explored the advantages and disadvantages of using these principles. Now, you can transform your organization into a model of quality and efficiency. Encourage your team to embrace these principles and commit to continuous improvement.

Fatih is a content writer at forms.app and a translator specializing in many text domains, including medical, legal, and technical. He loves studying foreign languages. Fatih especially likes to create content about program management, organizational models, and planning tools.